"You can sharpen chainsaw chain?"

It was forehead-slapping moment. "You've never sharpened your chain before? What do you do when it gets dull?"

"Buy a new one? It's only a few dollars."

I'd have to forgive him for his ignorance. It wasn't exactly that he was too lazy, but rather that he honestly didn't know that saw chains were sharpenable. Still, I pressed the point. You don't go buy a new pocketknife every time it gets dull, even though it's only a few dollars, now do you? Since I figured that there are probably quite a few folks at home who probably didn't know about saw chain sharpening, either, I thought I'd write a little bit of instruction about it.

What you need:

- a round file, in the proper diameter for your saw

- a flat file; most any will do

- a depth gauge

- a vise is helpful, but not necessary

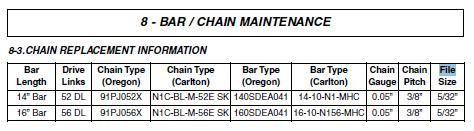

It's quite fast and easy to do. The most difficult part, in fact, might be figuring out what tools you need and finding a place to buy them. I'll walk you through that first. Your saw's operating manual should specify what diameter of round file your chain requires. Most Stihl and Husquevarna saws use a 7/32 file, but our McCullough needs 5/32. If you don't have your operating manual handy, you can search for your saw's make and model on the internet to download one. Some companies will even mail one to you, along with fun safety graphics. Here's a picture from my saw's .pdf manual:

Where can I find such a file, you might ask? We bought ours from our local hardware store. Some of the bigger chain stores might have them, or you can order them online. Or, if you're the kind of person who needs an excuse for random adventure, just drive down the road till you see a STIHL sign on somebody's workshop, barn, or storefront and ask them where to get one.

Any place that sells small round saw files probably also sells depth gauges. You'll only need one every third or fourth time you use the round file. The purpose of the depth gauge is to check the height of the raker -- the front part of your saw's tooth -- against the height of the actual cutting tooth. This difference in height is critical, because it controls how much wood the teeth chew off every time they pass through your log.

If you have a vise, set your saw's bar in it to hold the chain still while you sharpen. Take off the chain brake so you can spin the chain. It's wise to wear gloves so you don't nick your hands, although I usually don't bother. I marked the first tooth I sharpened with a blue sharpie. Use the round file to push from the inside, short edge of the cutting tooth to the outside. Pull the chain towards you to advance to the next tooth. Sharpen all the teeth on one side of the bar first, and then do the teeth on the other side. Our saw, which has been used for years without a single sharpening, still only needed about eight minutes of filing to bring it back to good-as-new.

If you have a vise, set your saw's bar in it to hold the chain still while you sharpen. Take off the chain brake so you can spin the chain. It's wise to wear gloves so you don't nick your hands, although I usually don't bother. I marked the first tooth I sharpened with a blue sharpie. Use the round file to push from the inside, short edge of the cutting tooth to the outside. Pull the chain towards you to advance to the next tooth. Sharpen all the teeth on one side of the bar first, and then do the teeth on the other side. Our saw, which has been used for years without a single sharpening, still only needed about eight minutes of filing to bring it back to good-as-new.About every third or fourth time you sharpen the teeth with the round file, you'll need to check the depth of the rakers. Set the depth gauge over your bar so that the high part is on the tall cutting edge of a chain tooth, and the raker is lined up with the groove. If the top of the raker sticks up over the top of the gauge, use the flat file to shorten it.

One of my favorite tools is the stump vise, pictured in orange. I discovered it while working as a sawyer for a wildland fire crew in North Carolina. The stump vise is designed to be small and light enough to ride around in your rucksack on the trail. When you need to sharpen your saw, you just pound the teeth into any nearby piece of stump or downed log, and it will hold your chainsaw bar still for you while you sharpen. It's been my experience that a saw chain benefits from a sharpening after about four hours of continuous use. If you're cutting all day on a fire or trail-maintenance crew, you can make two or three passes with the round file over each tooth while you're waiting for the saw to cool before you refill the gas tank. Enabling your saw to work harder makes you and your crew less fatigued.

One of my favorite tools is the stump vise, pictured in orange. I discovered it while working as a sawyer for a wildland fire crew in North Carolina. The stump vise is designed to be small and light enough to ride around in your rucksack on the trail. When you need to sharpen your saw, you just pound the teeth into any nearby piece of stump or downed log, and it will hold your chainsaw bar still for you while you sharpen. It's been my experience that a saw chain benefits from a sharpening after about four hours of continuous use. If you're cutting all day on a fire or trail-maintenance crew, you can make two or three passes with the round file over each tooth while you're waiting for the saw to cool before you refill the gas tank. Enabling your saw to work harder makes you and your crew less fatigued.While you're at it, run that flat file across the blade of your ax or maul, too. It's remarkably similar to sharpening a knife. Would anyone reading this like a more detailed explanation of how to do those things, too?

Wonderful. This, I've never done before. Thanks!

ReplyDelete~Faith